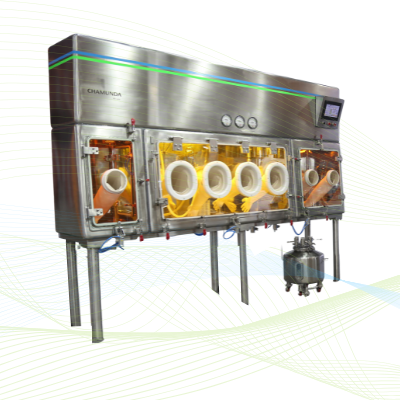

Sampling & Dispensing Isolator

Features

- Negative pressure Isolator with dedicated air extraction system

- Turbulent airflow pattern within the work zone

- Grade “D” (Class-8) air classification attained prior to product exposure inside the chamber

- All filters are continuously monitored by differential pressure gauges

- All filters are safe changeable, to avoid cross-contamination of product and operator

- Chambers made of SS 316L to provide high chemical resistance

- Catch pot for collection of washed water

- Gullwing type toughened glass door in front and rear of the chamber with safety locks

- All doors will be locked during the operation mode. Only the pass box front can be allowed to transfer the product in it. All doors position are monitoring by sensors.

- FDA approved food-grade seal and gaskets

Sampling & Dispensing Isolator is to provide the highest level of operator protection during Sampling and Dispensing activities of powder. The Products to be handled are designed with an OEL level of 1-10 micrograms/m3 for 8 Hours. The containment equipment is working under Negative Pressure and the operation of the Isolator shall not create a static dust layer that cloud becomes airborne elsewhere in the facility. The Isolator is provided a Grade “D” environment within the working area.